Lean

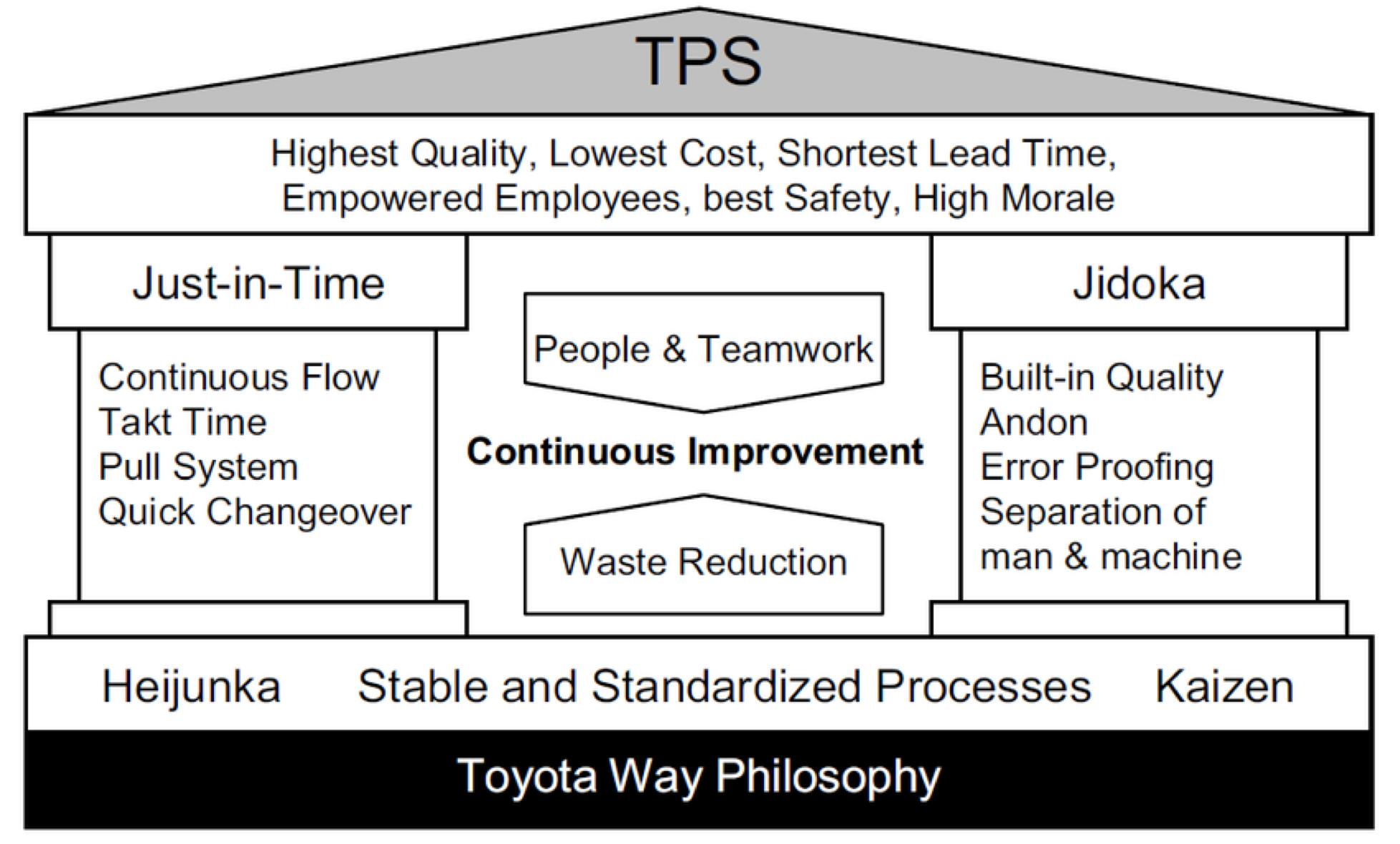

The Toyota Production System (TPS) has two pillars: Just-in-Time and Jidoka.

TPS/Lean focuses on reducing the waste (unnecessary code, meetings, documentation, bugs, ...) in a system and produce a higher value for the final customer.

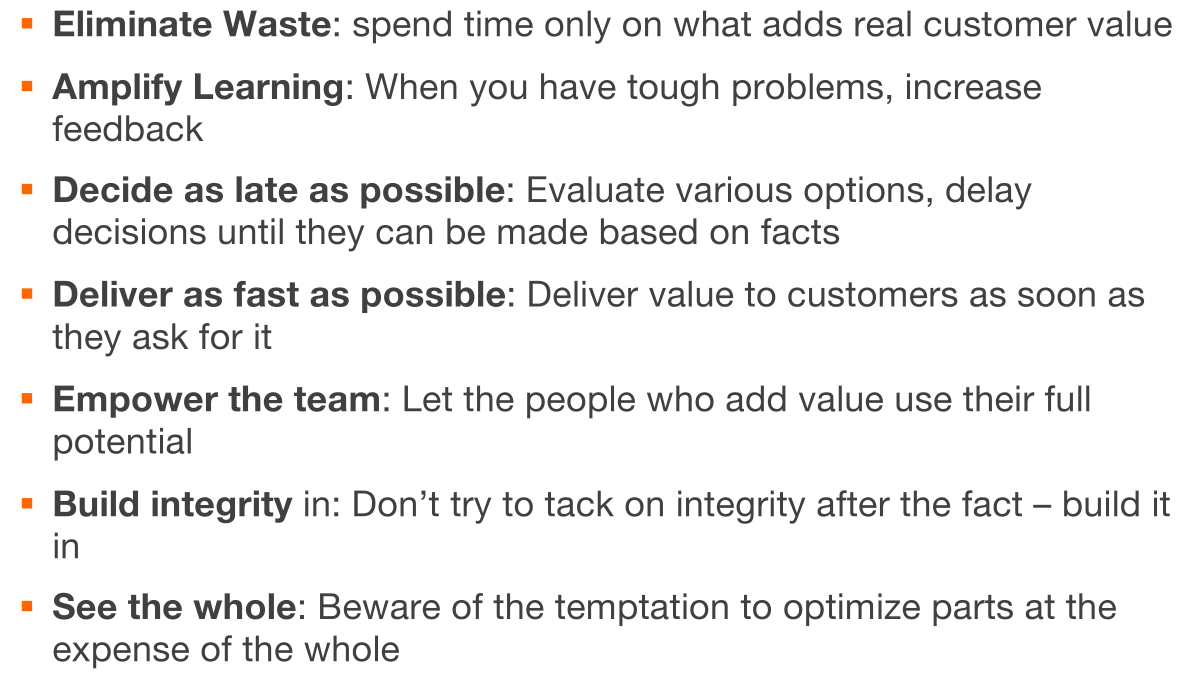

The followings are the principles of lean:

There are three types of waste:

- Wasted code Code which is either partially completed, outdated, unnecessary or defected

- Project management Processes which aren't necessary, hand offs (there is a loss of knowledge), or extra features

- Waste in work force

- Task switching slows people down

- When people wait for instructions or information